Hybrid Catalysis B.V. was founded in 2005 to offer cost effective and highly competitive catalysis R&D. Now, we run a state of the art laboratory located in Eindhoven, The Netherlands. Hybrid Catalysis is capable of making, optimizing, and testing virtually any catalyst, ligand, or compound. Sophisticated custom-built process skids and a kilolab are available.

Gijsbert Gerritsen, Jos Wilting and Arjan Koekkoek are Hybrids senior scientists. Their joint expertise covers almost any topic and technique in catalysis. Professor Emiel Hensen, scientific advisor, is a specialist in heterogeneous catalysis with a deep understanding of catalytic phenomena, both at molecular and at industrial level. Managing director Erik Abbenhuis is author on many scientific publications, next to inventor on over 30 patents. Abbenhuis, a former associate professor at TU Eindhoven, founded Hybrid Catalysis in order to follow his passion for invention.

Please consider us as an extension of your own research organization. We offer contract R&D at fixed rates. All our quotations list clear deliverables and lead times. Every project proposal contains the elements you need to manage progress and budget. At the bench, your project is carried out by a motivated, PhD-level team with experiences including synthetic chemistry, high-throughput screening, chemical engineering, flow chemistry, catalyst shaping, informatics, scale up, and construction of custom setups. We really know about catalysis and meaningful research.

All projects are handled strictly confidential starting at inquiry level. Wherever we can, we work on an exclusive basis. This means that all IP generated belongs to the customer, free of royalties. In general, projects involve periods of a few weeks to six months. For the larger projects, we, ourselves, invest in equipment when needed.

Our laboratory is equipped for working with chemicals, gases, and pressure reactors. We can make changes to our infrastructure when required and have a network of subcontracted experts. Where required, they provide services such as: glass blowing, pipe fitting, metal machining, (electronic) assembling and custom software development. Being a small company enables us to act very fast.

We have the equipment, or we will set it up, customized for your project. Also, we have access to any technique for catalyst characterization.

Many projects require setups that are not commercially available. These are examples of special equipment you can find in our laboratory..

Fully automated process skids with on-line analytics for gas phase process development.

Batch, fed batch, and flow reactors for liquid and gas / liquid process development

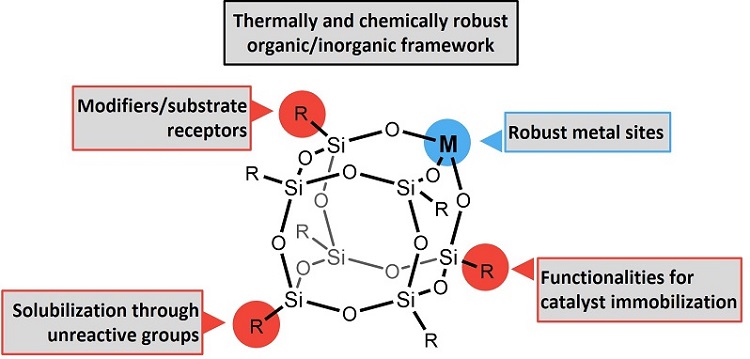

Our own development relates to decades of pioneering work involving metal silsesquioxanes. These well-defined materials are now readily available for transesterfication, epoxidation, olefin metathesis, polymer curing and many fine chemical applications.

Being an SME, we complement the pioneering work of universities. This is evident from our role in several EU projects that contribute to the energy transition and to the use of renewable feedstocks:

CO2 based fuels, CO2Fokus (H2020 project 838061), program on secure, clean, and efficient energy. Role: development and 3D printing of innovative hydrogenation catalysts. Testing of catalyst monoliths in hydrogenation of CO2 to dimethyl ether. For this purpose, a mini plant was built at Hybrid Catalysis.

Lignin valorization, SUBICAT (FP7 project 607044), Sustainable Biomass Conversions by Highly Efficient Catalytic Processes. Role: Exploitation of lignin as a new catalyst support. A PhD-degree was awarded as a result of this work to a young member of Hybrid Catalysis female staff.

Levulinic acid hydrogenation, GreenSolRes (H2020 project 720695), BBI program on Bio-based industrial innovation. Role: Kilogram synthesis of TRIPHOS ligands and homogeneous catalysts derived thereof. Multi kilo scale batch hydrogenation of levulinic acid to gamma-valerolactone and 1,4-pentanediol. The kilogram synthesis facility at Hybrid Catalysis proved essential for this project.

Methane steam reforming, ReforCELL (FP7 project 278997), Advanced Multi-Fuel Reformer for Fuel Cell CHP Systems. Role: Kilogram synthesis of an innovative methane steam reforming catalyst. Using a dedicated process skid, outstanding catalyst performance was demonstrated for a long time on stream at relatively low temperature.

Methane dehydroaromatization, ZEOCAT-3D (H2020 project 814548), call for Nanotechnologies, Advanced Materials, Biotechnology and Advanced Manufacturing and Processing. Role: supply of heterogeneous catalyst material for 3D printing of catalyst monoliths by the Belgium-based institute VITO. Catalytic monoliths were successfully tested in dehydrogenation / aromatization reactions.

Methane to hydrocarbons, DEMCAMER (FP7 project 262840), Design and Manufacturing of Catalytic Membrane Reactors by developing new nano-architectured catalytic and selective membrane materials. Role: timely supply of heterogeneous catalysts to the project consortium for various applications: Fischer-Tropsch, oxidative coupling of methane, wet and dry methane reforming, alkane isomerization and dehydrogenation. Kilogram synthesis of an innovative methane steam reforming catalyst. Using a dedicated process skid, outstanding catalyst performance was demonstrated for a long time on stream at relatively low temperature.